How Premium Shirts Are Manufactured in Turkish Textile Factories?

Inside a Turkish Textile Factories: How Premium Shirts Are Made for Global Brands

Introduction

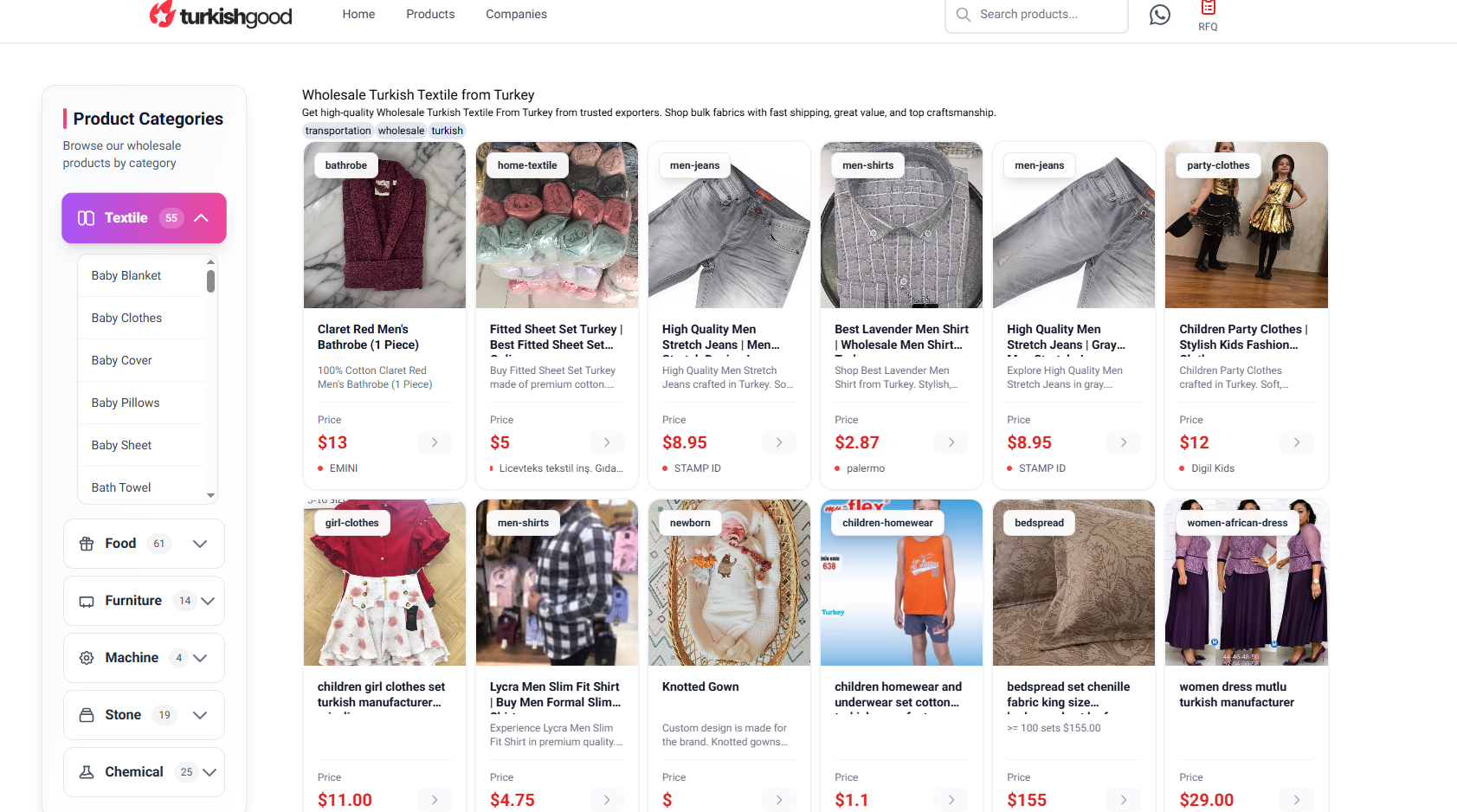

Have you ever questioned yourself about how the high-quality shirts in the display rack in your preferred store are manufactured? When you are procuring wholesale Turkish textile goods, you will be surprised by things that happen behind the scenes. Turkey is now a giant in the garment production industry, and it is no wonder the world-renowned brands continue to revisit. We will have you inside a Turkish textile factory manufacturing process so that you can see how these quality shirts are made.

The Turkish Textile Advantage

Turkey is not another manufacturing center. It is also well placed between Europe and Asia, and this implies that shipping time will be shorter and logistics will be improved. Moreover, the Turkish factories are integrated with modern technology and ancient craftsmanship.

This is why the Turkish textile production is unique:

- Good cotton sourcing by local suppliers

- Experienced labour force that has worked in textile work

- State-of-the-art machines that are of European quality

- Stringent production quality controls

- Flexible minimum order quantities (MOQs)

- Affordable rates without a reduction in quality

What is more, Turkish manufacturers are aware of the world's fashion trends. Not only are they producing clothes, but they are also producing products that are in tandem with the global market requirements.

Step 1: Choice and Preparation of Fabrics

The process of selling the men's Turkish shirts wholesale in Turkey begins with picking the fabric. The managers of the factories select the materials used by the factory very carefully according to the specifications of the client. They can be cotton, cotton-blend, or premium synthetic.

Step 2: Making and Cutting Patterns

Pattern makers develop templates as per design requirements. They apply CAD (Computer-Aided Design) software in order to be precise. The sizes, beginning with small and going to XXL, have their own pattern.

Sewing and Assembly

After cutting, the pieces of fabric are transferred to the sewing floor. It is here that the magic is done.

- Collar experts sew collars very accurately

- Sleeve professionals ensure perfect armhole attachment

- Button technicians place and secure buttons precisely

All the operators specialize in their respective fields. One shirt passes through 15–20 hands before completion.

Factories also invest heavily in workforce training, ensuring quality standards and productivity.

Quality Control Checkpoints

Quality is checked throughout the process:

- Stitch quality and thread tension

- Button positioning and security

- Collar symmetry

- Hem finishing

- Overall fit and drape

Any defect is corrected immediately, keeping rejection rates extremely low.

Step 3: Finishing Touches

Shirts are ironed using industrial presses and prepared for retail presentation. Optional processes include enzyme washing, printing, and branding.

Private labeling services are widely available in Turkish factories.

Step 4: Final Inspection and Packaging

Before export, each shirt undergoes final inspection for:

- Loose threads

- Color consistency

- Size accuracy

- Overall presentation

Only approved products are shipped.

Why Global Brands Choose Turkish Manufacturers

Global brands favor Turkey for its quality, capacity, and flexibility. Factories handle both large-scale and boutique orders efficiently.

Government export support programs help maintain international and ethical production standards.

Sustainability in Turkish Textile Production

Modern factories adopt:

- Water recycling systems

- Organic cotton sourcing

- Reduced chemical dye usage

Sustainability is becoming the industry standard.

Advantages of Sourcing from Turkey

- Fast turnaround: 30–45 days

- High customization: fabrics, buttons, labels

- Design support & sampling

- Competitive pricing

Conclusion

The journey from raw fabric to finished shirt in a Turkish textile factory is detailed and impressive. This expertise makes Wholesale Turkish Men Shirts from Turkey highly demanded worldwide.

For retailers and brand owners, understanding this process highlights the value Turkish manufacturers provide—world-class quality at competitive prices.

Frequently Asked Questions

Minimum order quantity of Turkish shirt manufacturers?

Most factories accept low MOQs when starting new partnerships.

What is the production time?

It depends on order complexity and fabric availability.

Do Turkish manufacturers offer custom designs?

Yes, most provide full customization, sampling, and design services.

How competitive are Turkish prices globally?

Typically 15–30% more competitive than European producers in similar categories.

For more information visit our

Pinterest Account